Sizing Machine.

Typical features of our sizing machines are their high operator convenience and perfect process control; the sized warp beams ensure maximum efficiency in weaving. Combination size boxes with and without prewetting device ensure short yarn paths. Machines designed as one-box version (floor-type execution) and as double-box version (overhead execution) can be offered in different constructions to meet every requirement. Cylinder driers in various arrangements guarantee a rapid and gentle drying of the yarn.

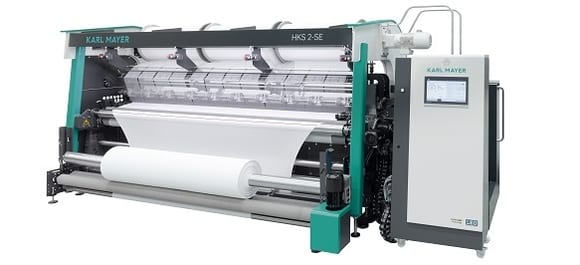

Karlmayer-200MP Pro size Hign Performance and Innovated Sizing Unit.

Daily Production Capacity 22 Thousand Kg/Per Day

Starch, carboxymethyl cellulose (CMC), wax, emulsifier, and polyvinyl alcohol (PVA)

Various substances that are used to facilitate the water-resistant protection of a paper's surface.

Wrapping

The warper is the machine that prepares the warp, so that it can be used on the loom, through the operation called “warping”.

This process consists in placing reels – made of cotton or silk threads – in a creel, the small machine placed next to our vertical warper.

Consists of several parts such as creel, open reed, head stock, warping drum etc.

The yarns in the sheet should be in a uniform spacing.

The yarns in the sheet should be of a predetermined length.

2 Nos Karlmayer

1200 MPM

Boiler

The most common type of boiler system especially for industrial uses, fire tube boilers, has been around for a long time because of their ability to meet steam needs when the demand is large and constant.

Forbes/Marshall for Latest Technology with Auto Fueling Syatem.

The function of a boiler is to either produce hot water or steam.

Normal boiler pressure should be between about 1-2 bars.

It should have maximum steam generation rate with minimum fuel consumption.

It should rapidly meet the fluctuation of load.